Respublika Park shopping mall presents documentary film about veteran Stepan Korobkin who conquered Kilimanjaro

06.08.2025 08:59

06.08.2025 08:59The CEO of one of the largest Ukrainian manufacturers of commercial refrigeration equipment talks about the relevance of customized equipment, the introduction of innovations and the peculiarities of developing new equipment to meet retailer requirements.

Retail is one of those areas where changes are happening all the time. Customers are becoming more and more demanding, increasingly paying attention not only to the price and quality of goods, but also to the store environment, level of service, convenience of equipment, and much more. Oleg Antonenko, the founder and CEO of Aisberg, one of the largest Ukrainian manufacturers of refrigeration equipment, told RAU how retailers and engineers are working together on new modifications of commercial equipment to meet the growing demands of their customers.

– How relevant are custom developments in the field of commercial refrigeration equipment for modern Ukrainian retail today? Which store formats or food service establishments mostly order customized equipment?

– Retail is developing in many formats, and depending on the types of sales and product groups represented in a specific format, the need arises for certain custom developments. Small-format stores usually have no need for customized equipment. Such stores are opened with minimal investments and a standard set of serially produced equipment.

In delicatessen and specialty stores (meat, fish), as well as in medium- and large-format stores, there is a need to create special product displays for more effective sales. Some retail chains prefer combined forms of product sales, both through a salesperson and via self-service, which requires special display cases. Many retailers have their own unique vision of product presentation and want to stand out from competitors. That’s when true creative engineering begins, and we enjoy creating new solutions together with our partners.

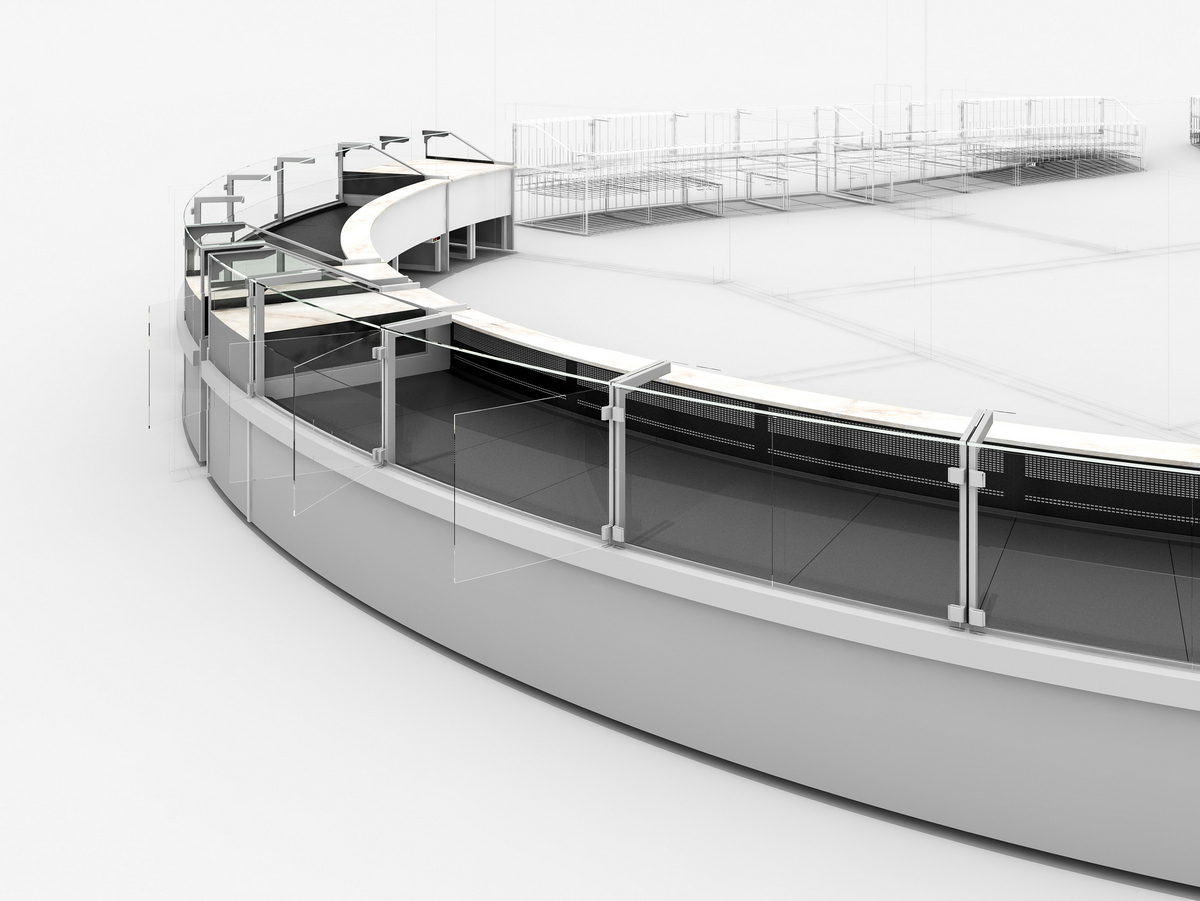

Combined display case with three refrigerated compartments – developed for the USA

– What is the basis for the effectiveness of custom technical developments? Are there advantages of customized equipment over serial models?

– The effectiveness of new technical developments lies in ensuring proper temperature and humidity control, as well as in effective product display. In self-service stores, products sell themselves. Sales efficiency in self-service directly depends on how the presentation is organized. This includes principles of good product visibility and quality lighting. Operational aspects are also important, especially for display cases with built-in refrigeration units used for unpackaged products.

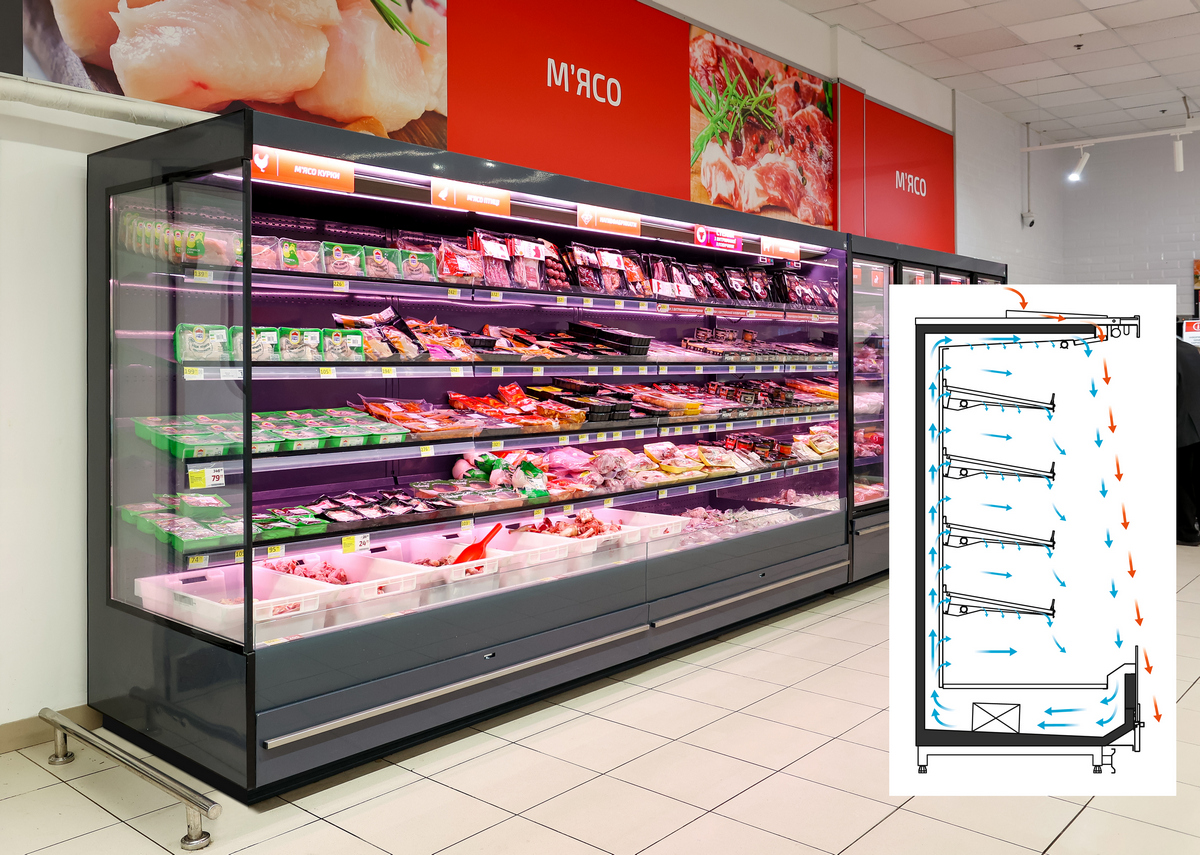

Promo Meat refrigerated display case for self-service meat sales (developed for Tavria V) and Promo FV refrigerated display case for vegetables and fruits (developed for Daas, Romania)

Medusa Meat refrigerated display case with ventilated shelves for fresh meat – developed for Velmart

Combined display case with pull-out drawers for meat sales – developed for Varus

New equipment undergoes laboratory testing. The second stage is in-store trials. Almost none of our customers share full data on how effective a given technical solution turned out to be. If a model proves its effectiveness in operation, it will definitely be reordered. Thus, the effectiveness of a new model equals the number of new orders.

Usually, our partners develop new equipment modifications together with us. Later, they adopt them as a standard for their retail network. This is how custom equipment becomes serial.

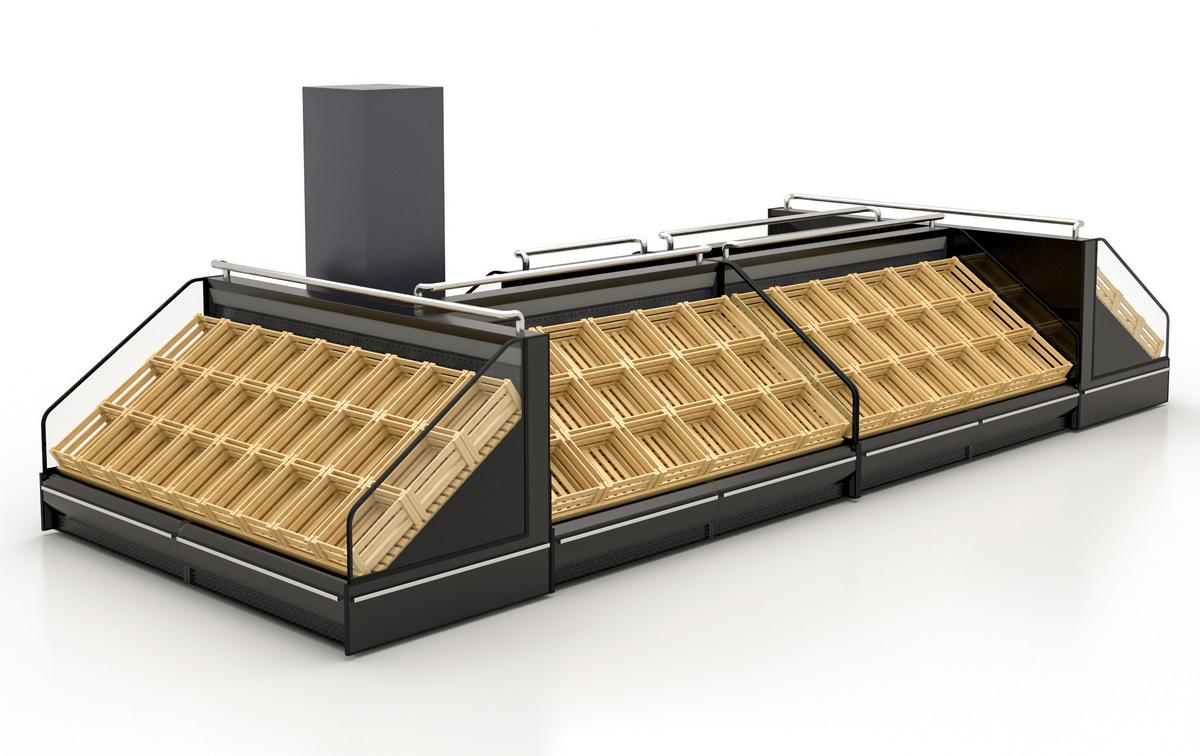

Orange Plug-in autonomous refrigerated displays with maximum visibility for fruits and vegetables – developed for Carrefour

Refrigerated display case for chocolate with humidity control system (40–50%) and +15°C temperature – developed for Silpo

Butterfly Plug-in refrigerated islands with autonomous cooling system and an irrigation system for vegetables and fruits – developed for Silpo

Refrigerated fruit island – ordered for Armenia

– For which product categories is customized equipment mainly ordered?

– Custom refrigeration equipment is ordered for almost all product categories – vegetables, fruits, culinary products, pickles, meat and fish, wine sales equipment. Even wall-mounted shelving units, usually considered purely serial equipment, are designed for specific projects – with special shelf width, body design, evaporator position and construction, temperature, finishing, etc.

Panoramic refrigerated display cases with transparent rear walls – developed for a city seafood shop

Medusa refrigerated display case with semi-circular shelves for fruits and vegetables – developed for Delicate

Nowadays, many stores organize fresh food production. And not only for direct sales in trade departments where technological equipment is integrated into the sales line. One of today’s trends is small cafés inside supermarkets and shopping centers. For this, we produce special complete equipment lines, always customized, though they may consist of already developed modules. The individuality of such lines depends on the café’s menu. Since no two menus are alike, the lines also have their own unique features.

Compact equipment line for food preparing and selling— developed for Velmart

Service line for Ultramarket cafeteria

– What principles do you use in equipment design? Is customized equipment much more expensive than serial models?

– Aisberg’s design principles are embedded in the company’s concept. The construction and design of the equipment, the cooling system, and energy-saving technologies must ensure increased sales and reduced store expenses – the Technology of Effective Trade.

Our main principles are:

Notably, cost is not among them. The starting price of equipment is important, but not decisive, since an efficient refrigerator with low energy consumption and quality cooling is far more profitable in operation than a cheaper analogue.

Cube line of display cases with “mist” sprinkling system for fish – developed for Velmart

Corner module with “mist” sprinkling system for fish integrated into a gastronomy island — developed for OnDe gastrogallery

Semi-circular refrigerated display case with custom bending radius – developed for Galmart, Uzbekistan

– How are engineering ideas born? Do you use the experience and developments of other manufacturers? How long does it take from placing an order to installing equipment in a store?

– We fundamentally do not copy or steal other manufacturers’ designs. We create our own. Most ideas are developed together with customers. Sometimes, however, it’s purely Aisberg’s engineering creativity – as with the Diagonal line of display cases. Here, we often look into the future, relying on our own intuition and vision of prospects.

Refrigerated display cases in Diagonal design at EuroShop-2017, Germany

Comfort Diagonal refrigerated island with built-in low-temperature combined display case and column-bypass module – developed for Velmart

Specialized Diagonal refrigerated display case for selling olives – developed for Grand Majidi Mall, Iraq

Diagonal hot display line with module for made-to-order pizza preparation – developed for Grand Majidi Mall, Iraq

Aisberg engineers have accumulated significant experience in developing custom technical solutions. In 90% of cases, we manage to create equipment that requires no major adjustments after producing the prototype. Production time depends on complexity – sometimes 1.5–2 months, sometimes longer.

All new equipment undergoes laboratory testing. We certainly monitor the operation of the first units in stores. If necessary, we make improvements under real operating conditions. Everything depends on how accurately the operational task was formulated and whether it matches reality.

Refrigerated and heated culinary display cases with inclined presentation surface – development for Silpo

– Does customized equipment mean only refrigerated furniture, or also cooling systems?

– Aisberg develops not only display cases but also customized cooling, defrosting, and heat recovery systems. Many of these developments are patented as inventions and utility models – Eurasian Patent 012195, Ukrainian Patents 114635, 105207, 25036, 77925, 23288, and others.

Cooling station with receiver group and heat recovery system in a container design – for Ultramarket

Supermarket cooling system with liquid defrosting system – for Carrefour

– Which projects are the most interesting for you?

– The most interesting projects are the ones ahead.